What is Swiss Machining?

We’ve all heard of CNC machining, but what makes a Swiss CNC machine truly different from traditional lathes?

The Swiss-Type Lathe

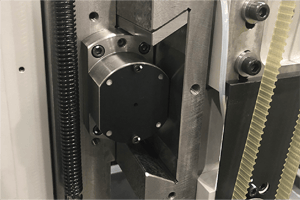

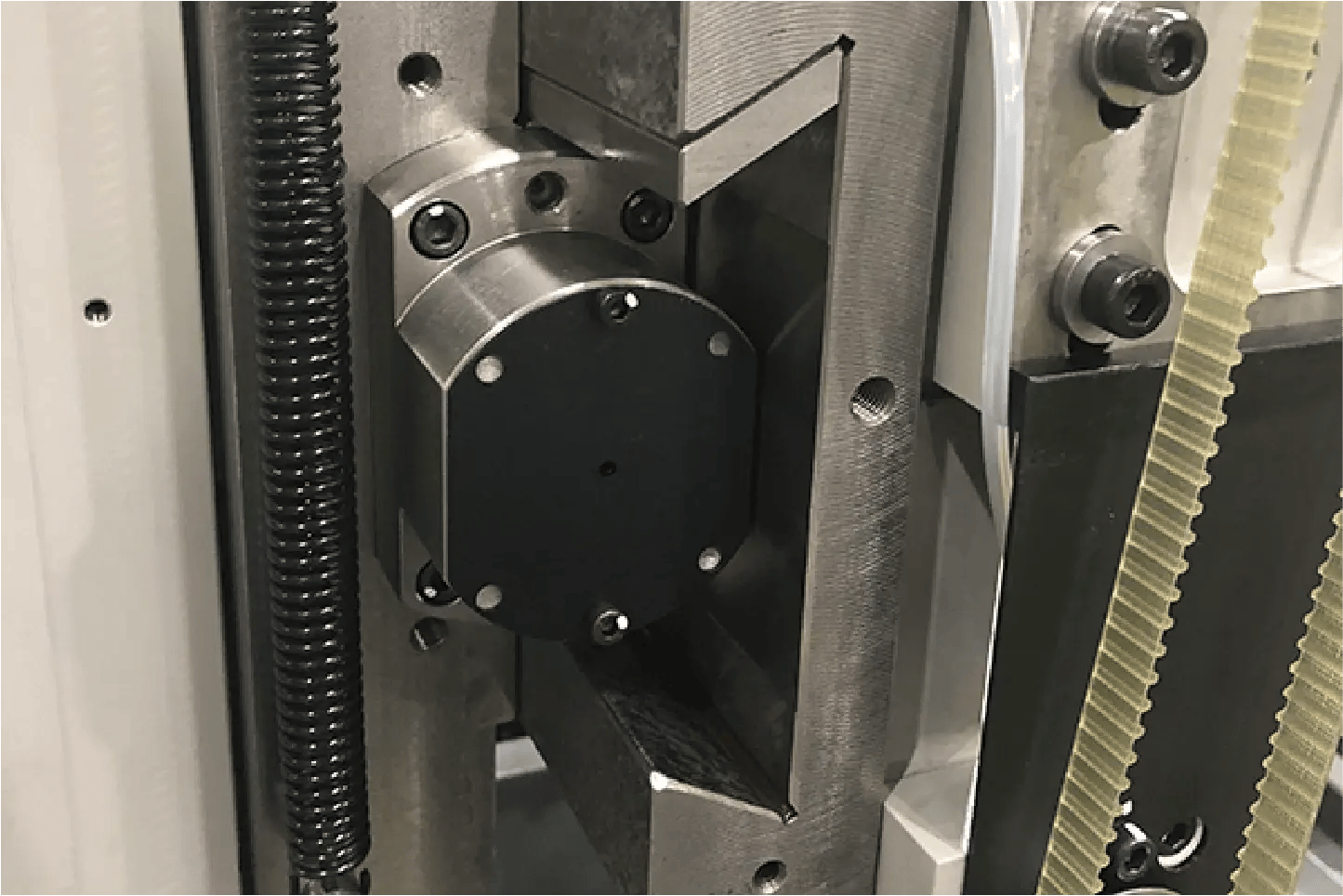

The Swiss CNC machine, once confined to niche applications, was initially favored for its proficiency in crafting intricate, small, and elongated components. Functioning as a variant of the standard CNC lathe, this specialized turning apparatus directs bar stock through a guide bushing, facilitating tool engagement close to the supportive point.

The Swiss-Type Lathe

The Swiss CNC machine, once confined to niche applications, was initially favored for its proficiency in crafting intricate, small, and elongated components. Functioning as a variant of the standard CNC lathe, this specialized turning apparatus directs bar stock through a guide bushing, facilitating tool engagement close to the supportive point.

Swiss CNC Machine Benefits

The Swiss CNC lathe configuration enhances stability, enabling the machining of delicate parts with exacting tolerances at elevated speeds. Additionally, Swiss CNC machines possess the capability to mill intricate parts, an increasingly indispensable feature in modern industrial settings.

When evaluating a Swiss-type lathe, critical considerations include the complexity of parts, required tolerances, and the dimensions of the bar stock.

Superior Swiss Machining Means

Swiss CNC machining provides short manufacturing cycle times. Produce more parts in less time with short, quick movements.

Nomura DS Swiss CNC Machine Technology is known for

Are You Ready for Your Swiss CNC Machining Solution?

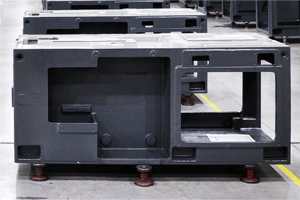

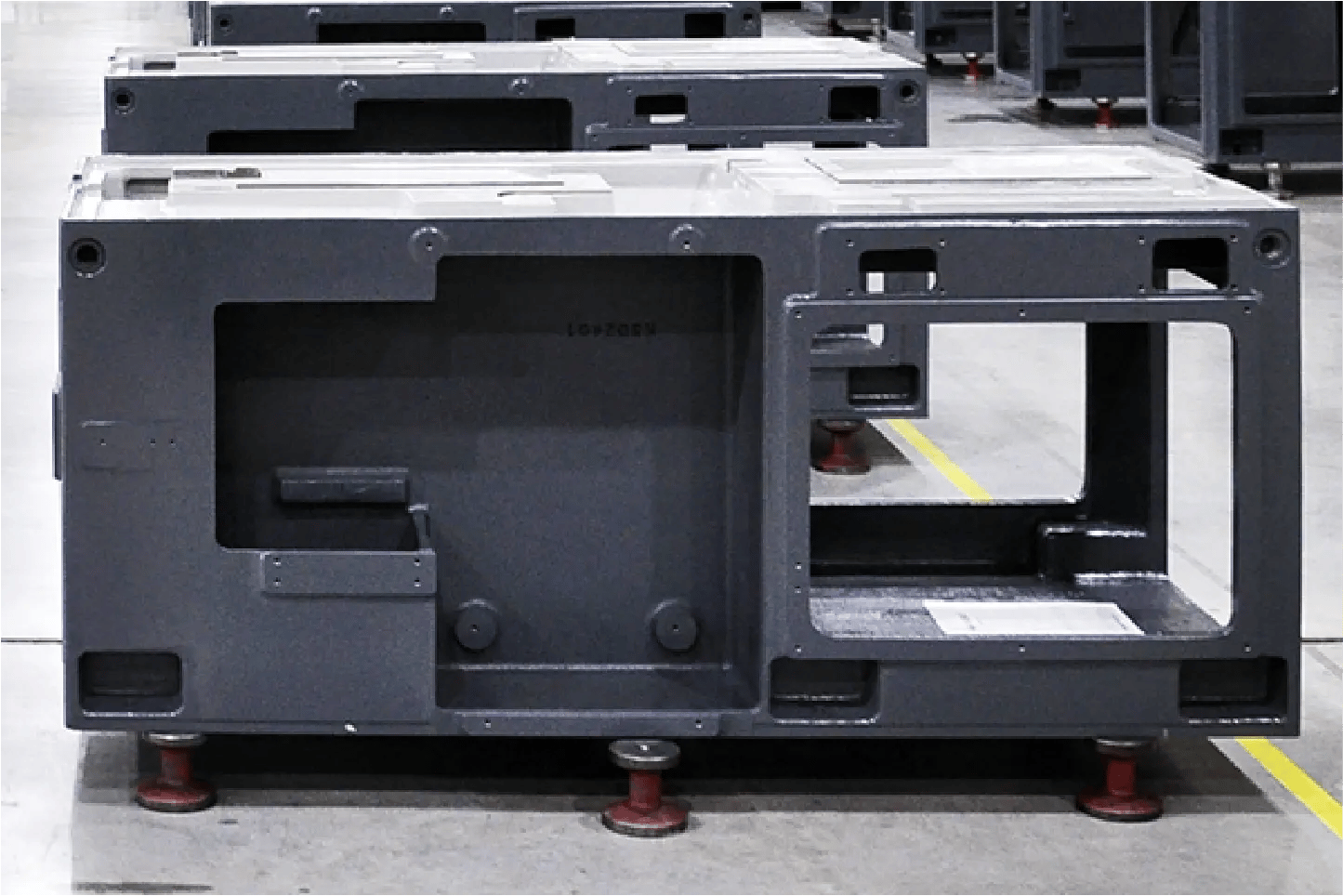

Learn how a Swiss CNC Machine will help streamline your machining processes through reduced operations, increased productivity, stability, and rigidity for the most intricate pieces at the fastest rate.

Explore our range of Swiss CNC turning machines today and discover how our cutting-edge technology and unparalleled expertise can elevate your machining operations to new heights of success.